Design and Optimization of Disc Brake Using FEA

Abstract

One of a car's most crucial active safety elements is the disc brake unit, which is situated at the front axle. An essential part of the disc brake system is the brake disc rotor. The rate of friction between the brake pads and the rotor and the amount of heat released into the air define how effective this braking system is. It could harm the brake mechanism and cause it to overheat due to thermal stress which would cause the brake system to break down. Grey cast iron, stainless steel, and aluminium were the three main types of materials used in this study. In addition, three designs solid, semi-ventilated, and ventilated disc were applied in this investigation. As for design and analysis, thermal analysis and Solidworks were used. Based on the results, the ventilated disc brake is the best design in terms of heat transfer. Aluminium is a material with good heat distribution but cast iron can be consider as an option for production.

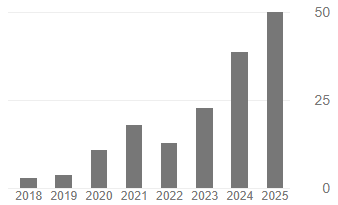

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.