Design and Development of Ultra Violet LED Machine

Keywords:

Photolithography techniques, PCB, Led technologyAbstract

Photolithography techniques on a PCB are a UV exposure process that used in micro fabrication to pattern parts of a thin film of a substrate. Light is use to transfer a geometric pattern from a photo mask to a light-sensitive chemical (photoresist) on the substrate. In educational institution, most of the UV exposure process used UV Florescent lamp or Metal Halide lamps as an exposure system, both of this equipment is expensive and produce a wide UV radiation that is not suitable for the PCB which will increase the consumption of the electricity. This paper aims, to describe the development of UV exposure device using LED lighting technology with low cost, portable and suitable for education facilities. LED lighting has powerful flexible design features and can be combining in any shapes to produce a highly efficient illumination. LED lights achieve higher application efficiency because the LED is design to focus the light direct to specific location. The LEDs can frequently switched ON/OFF, bright up immediately when powered ON and has great advantages for infrastructure projects such as in exposure system. These UV LED exposures designed by using combination LED circuit with controller board to control time, relay and LCD display. The UV LED circuit use in sized 120 mm x 190 mm with 3mm LED to produce 400mm to 405 mm wavelength for UV exposure system.

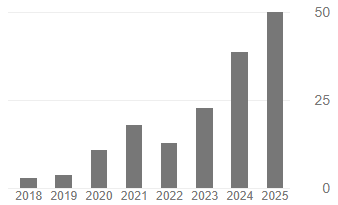

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2018 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.