A Preliminary Investigation of Interior Door Panel Assembly Improvement by Utilizing Fixture for B-segment Seven-seater Sport Utility Vehicle (SUV)

Abstract

The major role of a fixture is to allow for exact repeatability and interchangeability of products within the same manufacturing process. This article looks at a different approach to making door trim and demonstrates the proper jigs for assembly. The fundamental objective is to optimize the passenger door assembly process through the decrease in cycle time. A fixture development process is made up of several stages: recording initial cycle time, talking with process stakeholders, and using a design tool to create the fixture virtually. The cycle time analysis method is used to calculate the effect on process performance, and then the data is compared to see how process performance differs. The fixture design has the additional benefit of reducing the total manufacturing time for the door inside trim assembly while also increasing the production line's overall efficiency. While this inquiry is in the beginning stages, further cycle time analysis is required to ensure the validity of the findings.

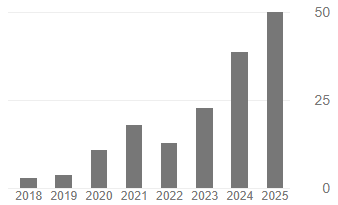

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.