Effect of ABS on the Mechanical Properties of PP/ABS Blends and Tensile Strength Using Taguchi Method

Abstract

Polymer blend becomes one of the effective methods in the development of polymer industries. By applying this technique, it can help to control the environment and create new material with better performance from a net polymer. PP and ABS are the most extensively used commodity polymer due to their good mechanical properties. The aim of this study is to identify the injection molding parameters of PP and ABS such as melt temperature, mold temperature, injection pressure and holding pressure and is to inspect the mechanical properties of hybrid material between ABS and PP such as tensile strength, tensile modulus, and elongation. The relationship between the control parameters and the output response for the hybrid material has also been determined. The samples of PP/ABS blends were prepared via injection molding and have been categorized based on weight percentage. The parameter setting was selected based on the data available in the literature and suggested from resin supplier which is mold temperature, melt temperature, injection and holding pressure. The results showed that with the addition of ABS, the tensile stress is reduced causing the material becomes brittle. With the increasing content of ABS in PP/ABS blends, the tensile modulus will increase while the percentage of elongation in PP/ABS blends decreased. Holding pressure was the most significant effects for tensile strength in PP/ABS blends found from Signal to Noise Ratio (S/N) in the Taguchi Method.

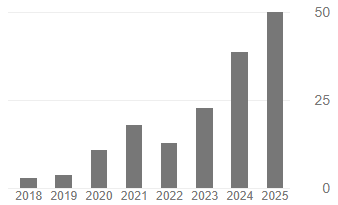

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.