Parameter Optimization of Friction Stir Welding Process by using RSM on Dissimilar Welded AA6061-AA7075

Abstract

In this study, the joining of dissimilar between AA6061 and AA7075 with thickness of 3 mm was perform by using a friction stir welding (FSW) method. Response surface methodology (RSM) was choose to optimize effective factors during FSW process. The result of process parameter on impact toughness of welded butt joint was studied. Rotational and transverse speed were the main process parameters which were taken into consideration. Three levels of the tool rotational and welding speed in the range of 900–1100 rpm and 90–110 mm/min were studied via a central composite design (CCD). The optimal process parameters were decided with reference to impact toughness of the joint. By using the optimum parameter, the projected optimum percentage of the impact toughness was confirmed by doing the experiment. The result indicated that the joint formed using the rotational speed is 1000 rpm and welding speed of 110 mm/min and 1100 rpm and 110 mm/min show the highest and lowest joint impact toughness is 5.404 J and 3.404 J, respectively. The joining impact toughness result is higher compare to the base metal. The Anova table has showed that the entire method are important to adequate the scientific model, where the residual blunder among investigational and theoretic is 3.02%. Microstructural observation has discovered the change of a recrystallization especially in SW region have significant effect on impact toughness and hardness test.

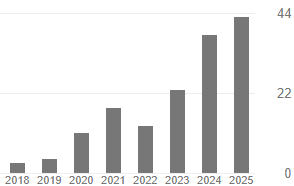

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.