Effect of Mesh Size on the Natural Frequencies of Lathe Spindle

Keywords:

spindle, modal analysis, mesh sizeAbstract

Improved computer numerical control (CNC) machine tool performance is critical in machining accuracy as modern manufacturing advances, particularly high-speed and high-precision machining. As a fundamental component of CNC machine tools, the dynamic properties of a spindle have a significant impact on machining performance. Modal analysis is one method for assessing the dynamic characteristics of mechanical components. Modal analysis is a process of extracting modal parameters (natural frequency and mode shape). This study aims to investigate how the mesh size of the finite element model affects the natural frequencies of the spindle. A three-dimensional model of the spindle was developed and analyzed in Autodesk Inventor software. Observation on changes of the natural frequencies was carried out by using a range of mesh sizes. The mesh size was controlled by varying the value of the average element size in AI modal analysis tool. The number of nodes and elements of the finite element models were compared, as well as the percentage of total error. Results revealed that mesh sizes have a significant effect on the accuracy in predicting natural frequencies. Differ in natural frequencies depend on the size of the mesh. Finally, significant research prospects are extensively explained based on present studies and will be critical in conducting modal analysis for machine tools spindle.

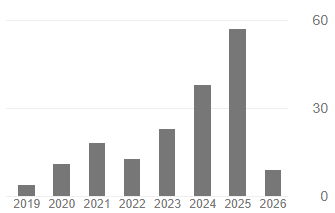

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.