Analysis of Mechanical Properties and Microstructure of Al-SiCp Metal Matrix Composite

Abstract

According on development of technology, composite materials are given first preference due to its high strength and less weight ratio. The main application of metal matrix composites is used in aeronautical and automobile applications. Aluminium is light weight materias, but it has lower mechanical strength. To improve the mechanical properties of Aluminium (Al), silicon carbide particle (SiCp) is added as reinforcement to Aluminium powder for preparing metal matrix composite. The metal matrix composite is produced by powder metallurgy method. This method is cheap and very effective. The composites was fabricated by variation of SiCp reinforcement from 0 % , 5 %, 10 % and 15 % wt. Four samples of the composite materials have been prepared according to testing for bulk density, compressive strength, vickers hardness and crystal structure. From the results obtained, the composition of SiCp reinforcement can influence siqnificantly on bulk density, compressive strength and vickers hardness. If the composition of SiCp reinforcement increase, the bulk density, compressive strength and vickers hardness tend to increase. The highest density, highest hardness and compressive strength are achieved at sample with 15 % SiCp at sintering temperature 650oC. According the XRD results show that it is found two phases such as Al phase and SiC at samples with 5 to 15 % wt. of SiCp.

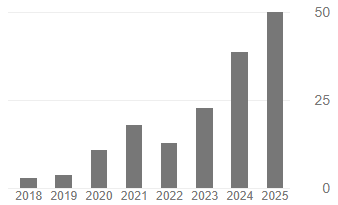

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.