Effect of Heat Treatment Temperature on Mechanical Properties and Micro Structure of DIN 1.2316 Steel

Abstract

The effects of varying temperature of heat treatment of DIN 1.2316 steel to mechanical properties and microstructure have been investigated. The samples were heated by using electrical furnace at 820°C, 860°C, 900°C for 1 hour, after that the samples were quenched in water. Then heat treated and quenched samples were measured vickers hardness and impact strength, the microstructure of samples were observed using optical microscope. . The test results show that with increasing heat treatment temperature can increase the value of vickers hardness. The hardness value before heat treatment was only 386.00 kgf / mm2, but the hardness value of samples after heat treatment at 8200C, 8600C, 9000C are respectively 391.29 kgf /mm2, 470.57 kgf /mm2 and 488.52 kgf /mm2. While the impact energy value tends to decrease with increasing heat treatment temperature, where the impact energy before heat treatment is 1550.00 J /mm2, and impact energy value of samples after heat treatment at 8200C, 8600C, 9000C respectively are 1320.15 J /mm2, 1110.35 J /mm2 and 950.00 J /mm2. The sample before heat treatment according to observation with optical microscope and XRD has ferrite (α-Fe) and pearlite (γ-Fe) phases. But the samples after the heat treatment process show ferrite and pearlite phase tends to decrease and emerging new phase martensite (α'- Fe). This martensite phase causes the material to become hard.

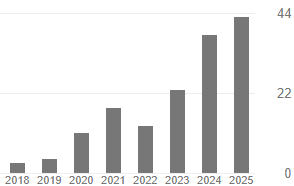

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.