Modelling Titanium Machined Workpiece Qualities Using Fuzzy Logic

Abstract

Titanium is an expensive material with superior qualities and preferred by manufacturing industries. The industries must consider machining operations and parameters selection to minimise the material waste and machining failure. Material waste related directly to machining operation used. Thus, EDM Die Sinking is the selected machining operation because of its extensive in reducing material waste. Moreover, machining failure which effected to machined workpiece qualities are associated with machining parameters. Furthermore, determining the machining parameter practically made by experienced machinist and is made by trial and error manner. Therefore, this paper aims to put forward Titanium workpiece qualities in relation to EDM Die Sinking machining parameters relation with Fuzzy Logic model. For comparison, ANN will also model the relation. The models development begins with data selection, modification, and composition. Then the selected models are designed with their features. Fuzzy Logic model features include selection of membership functions, feature range points for input-output, and fuzzy logic rules. In addition, for Neural Network model, Feed Forward Backpropagation Network is applied. Afterward, the network architecture and functions used is decided. Finally, the estimation performance of the models with various model designs are compared. Fuzzy Logic and ANN models best performance in estimating Surface Roughness is similar i.e. 83.3% detection rate. Fuzzy Logic with 97.2% detection rate is the best dimensional accuracy estimation performance. And the best dimensional accuracy estimation performance for ANN is 91.7%. The best performance model is substantial to the related industries because the model can reduce material waste and machining failure. Besides, the model simplified the parameters estimation and easy to new machinist.

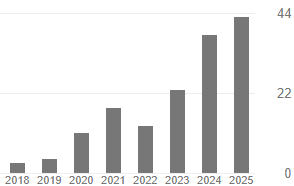

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.