Optimizing Abrasive Water Jet Machining Parameters on Cutting Hybrid Metal Matrix Composites Al7075 by Genetic Algorithm

Abstract

Hybrid Metal Matrix Composites (MMC) Al7075 is a difficult-to-cut material that required non-conventional machining to manufacture automotive, aerospace, and defence components. The composite with minimum Bottom Kerf Width is much desire than minimum Top Kerf Width by the industries. Furthermore, the material cut with less defective work piece can be achieved by Abrasive Water Jet Machining (AWJM), compared to other nonconventional machining. The minimum kerf width lessens the energy used and waste resulted. Moreover, cutting Hybrid MMC Al7075 by AWJM, adding the advantages such as of good quality cutting of composite material, lessen water usage and waste production. These facts formulated that this study aims to search the minimum TKW for three types of Hybrid MMC Al7071 composites machined by AWJM. The data in this study used to model machining parameters as the input and TKW as the output using regression analysis. The model used as fitness function for Genetic Algorithm (GA) to search the minimum TKW. And from this search result, the optimal machining parameters can be determined. Finally, the result of experimental data is compared to the search data. The comparison confirmed that by GA, lesser minimum TKW is obtained, with the lowest value is 6.93% decreased.

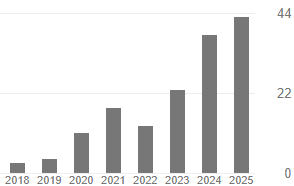

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.