Experimental Investigation on Mechanical Properties of Bagasse Reinforced PE Composite for Automotive Component

Keywords:

Polymer Composite, Polyethylene, Cane BagasseAbstract

The use of natural fibers as a polymer composite additive is one of the alternative in the production of automotive components. It adds value to the wasted natural ingredients while reducing the depleted use of petroleum-based materials and also reducing the impact of pollution on the environment. In this research, specimen of composite is constructed from polymer (polyethylene, PE) as the main ingredient and cane bagasse fiber as additives in three ratio of composition 60%:40%, 50%:50 and 40%:60%. The tests performed to determine the mechanical properties of the composite specimen are charpy impact and flamebility test. The study from the charpy impact test shows composite A, 60% PE:40% sugar cane bagasse fiber has provided a good ductility, strength and toughness. Meanwhile the results of flamebility test also shows a composite C 40% PE:60% sugar cane bagasse fiber has the best burn resistance properties. The significant combination of PE and cane bagasse fiber composite to produce the automotive component is 50%:50%, cause it provide good value to meet the mechanical properties of impact and flamebility. As a recommendation for improvement, smaller ratios are used for sugarcane fibers as a comixed PE to see more accurately the effectiveness and other mechanical tests such as

hardness and water absorption tests.

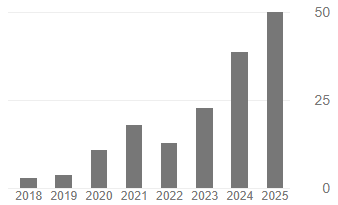

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2017 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.