Influence of Rice Husk and Composition Ratio on Mechanical Performance of Polypropylene Composite

Keywords:

Rice Husk, Composition, TreatmentAbstract

In this study, the surface modification techniques were performed on rice husk flour (RH) in polypropylene (PP) matrix and consolidated to improve the mechanical properties. The rice husks were formed with the granular size composite with such as untreated, boiled, and boiled-sodium hydroxide (NaOH) treated fiber. An internal mixer machine is set for four different composites compositions ratio and the samples produced by hot press machine. The analysis was carried out using a 2- factor and 3- level design of experiment (DOE). An analysis conducted based on variance (ANOVA) is to determine on how the formed of three type rice husk and the composition of the rice husk ratio affected the mechanical properties of the composites. It was proven that both the rice husk type and the composition demonstrated significantly different results in terms of the tensile test, impact test and hardness test. The overall results indicated that the boiled-sodium hydroxide (NaOH) treated rice husk fiber composite exhibited the highest performance.

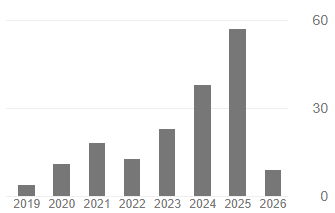

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2016 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.