Design for Automatic Automation for Batik Effluent Treatment System by PLC Controller Siemens Logo! 230RC

Keywords:

automatic, PLC Siemens, batik effluent treatmentAbstract

Automation of water treatment plant in batik industries has already been developed and widely used in Malaysia. However, the majority of the batik effluent treatment systems which is in small and medium scale batik industries are still using manual automation system. Unfortunately, by using manual automation system is time consuming especially when human supervision is required during a long cycle of batik effluent treatment. Therefore, this paper focuses on design of a system to cope with this problem by proposing a design of an automatic automation control system for batik effluent treatment embedded with Programmable Logic Controllers (PLCs) Siemens Logo! 230RC. PLC Siemens Logo! 230RC is used to communicate with input and output devices for batik effluent treatment system. The automatic automation system was designed and tested using a pilot plant which was installed at Nordin Batik and Craft, Kelantan. The results showed the overall time consumed by input and output devices (floating sensors, PH sensor, water pumps, blower and dosing pump) to treat batik effluent is t = 2 hours 25 minute per cycle. The comparison between automatic automation by using PLC to a manual technique in term of annual cost saving are analysed. As the results, RM 15101.30 is able to be saving yearly by using this automatic automation system. Hence, this system presented as an effective automatic automation system in term of reducing human supervision, time consuming and cost effective.

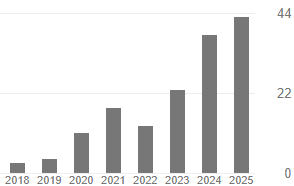

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2018 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.