The Effects of Cold Working on Corrosion Resistance of Implant Materials

Keywords:

Cold working, corrosion, stainless steel 316LAbstract

This experimental work regarding the effect of cold working on corrosion resistance of stainless steel 316L as application metal materials in biomedical. The research aim to investigate the influence of deformation that occurs through a process of cold working (rolling) on the corrosion resistance as implant material stainless steel 316L. At the beginning, this material will perform cold working (rolling) to make several products with different thickness. Next, the products will perform different method to find the mechanical properties testing (hardness) and corrosion testing (dipping into Hydrochloric acid HCl). Lastly, the characteristics of the product will be achieved by micro structure observation. Optical microscope will be used. The result it showed the effect of thickness reduction during rolling process for mechanical properties (hardness) from specimens test is increasing relevant to hardness of specimens. The value of hardness on the degree of deformation is expressed in the strain that shows the value of hardness of the material will continue to increase along with the amount of strain that occurs. Pore located in the grain becomes larger, so it's getting easier corrosion occurs when acid liquid (HCl) is applied.

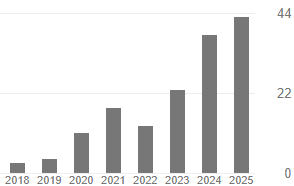

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2018 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.