Characteristic of Cement Mortar Containing Windscreen Glass Waste Powder

Keywords:

cement replacement, windscreen glass waste powder, pozzolanic, compressive strength, mortarAbstract

Cement is produce and manufactured on a large scale from the silicate industry and used mostly in building homes, industrial buildings and other structures. Cements are produce from raw naturally occurring materials and the production involved both mining and manufacturing components, and it is a major source of greenhouse gas emission. For sustainability, and to reduce the greenhouse gas emission cause by cement production, therefore it is highly time to look into the other possibility of replacing this cementitious material. This paper was conducted to effects of various proportions of Windscreen Glass Waste Powder (WGWP) on the compressive strength in mortar. The mortar was prepared by incorporating several compositions of WGWP (5%, 10%, 15% and 20% by weight of cement) and cement to sand (C:S) ratio of 1:3.0 were employed. Fixed water to cement (w/c) ratio of 0.5 was used for this study. The samples were water cured and the assessment of the strength performance of mortar cubes were carried out at 7, 28, 60, 90 and 120 days. Studies conducted have shown that WGWP has the good pozzolanic properties. In term of compressive strength, it was observed that the compressive strength increases with an increase in percentage of WGWP from 5% until 20% of replacement. The corresponding Strength Activity Index (SAI) with 20% WGWP were 85%, 78%, 80%, 81% and 85% at 7, 28, 60, 90 and 120 curing days respectively.

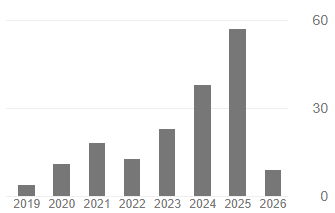

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2017 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.