A Pellet Forming Machine with Steel Wheel Pressing System Using Banana Sticks Raw Material

Keywords:

Banana Tree Trunk, Gedebog Banana, Fish Feed, Pellet FormingAbstract

Gedebog banana or banana stem is a part of the banana tree that is considered waste and is often thrown away, but it can be optimized to become a feed raw material with economic value. One of the benefits of banana gedebog is that it can be used as a mixture of fish feed which is formed with feed raw materials into pellets. Based on laboratory analysis, the content of banana gedebog includes Dry Material (BK). 87.7%, ash 25.12%, crude fat (LK) 14.23%, crude fibre (SK) 29.40%, crude protein (PK) 3% including amino acids, amine nitrate, glycosides, contains N, glycolipids, B vitamins, nucleic acids, extract ingredients without nitrogen (BETN) 28.15% including carbohydrates, sugars and starch. This research aims to produce a pellet-forming machine for fish feed using a mixture of banana gedebog as the raw material. The research method involves building a machine according to the design and testing of the machine using a steel wheel mould pressing system. This research results in a pellet-forming machine unit that can produce pellets utilising a mixture of banana gedebog as raw materials. Average printing results per minute, 3 mm diameter pellets = 1137 grams, 4 mm diameter pellets = 1607 grams and 5 mm diameter pellets = 1553 grams with an average machine capacity that can produce pellets reaching 75 kg/hour to 90 kg/hour.

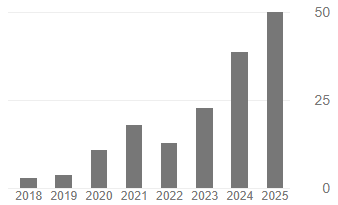

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.