Rekabentuk Optima Mesin Pembungkusan Roti Kering Menggunakan Kaedah Ruang Pembungkusan Terubah (MAP)

Keywords:

Modified Atmosphere Packaging, shelf life, breadAbstract

Bakery products have short shelf life due to its fragileness and moldy nature. The Modified Atmosphere Packaging (MAP) is an optimum packaging solution that can be applied to increase the shelf life of a product. At the moment, bakery retailers are only able to produce bread in small quantities due to the nature that is easily rotten and smelling murky. The objective of the study is to find the best method to improve the duration of bread sold in the market and identify the most suitable way to maintain the taste and dryness of bread. Hence, to identify packaging materials and the packaging technology which are appropriate to extend product life and durability. This study focuses on the concept of modified atmosphere packaging (MAP) to maintain the smell and taste of the original bread for optimal time duration. The proposed solution is to design a vertical sealer packaging machine and the flushing function for the packing and production of bread packed into a nylon PA wrapper. Air is included from the non-oil compressor to improve the product lifespan and prevent products from wrecking. Nylon PA is chosen due to its excellent technical characteristics of gas absorption. This machine is capable of wrapping the product up to 1000 packs daily compared to 600 packs per day using the manual

operation. In conclusion, the modified atmosphere packaging (MAP) applications in the bakery industries provide a great advantage in improving the shelf life of bakery products using suitable gas mixture to maintain the taste and fragrant of the bread.

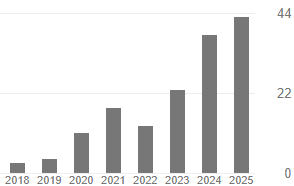

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.