Quarry Dust: The Potential of By-Product Waste as Sulfate Attack Resistance in Cement Composites

Keywords:

cement composites, sulfate attack, quarry dustAbstract

In this study, the durability of cement composites at 0 wt.%, 12.5 wt.%, and 17.5 wt.% of the addition of quarry dust was investigated against sulfate attack at 1,2,3,4,8,13 and 15 weeks. The specimens of cement composites were immersed in sodium sulfate solution and evaluated for length change and salt deposition. Cement composites with the addition of 12.5 wt.% of quarry dust were found to possess the best sulfate attack resistance. The sodium sulfate solution was found not to affect the original length of the cement composites at all percentages of quarry dust. A visual examination revealed that the cement composites without the addition of quarry dust showed the existence of salt deposition compared to 12.5 wt.% and 17.5 wt.%. The quarry dust consumption presented the cement composites' durability improvement due to sulfate attack. The silica content and filing effect of quarry dust chemically react with the calcium hydroxide released by ordinary Portland cement to form durable cement composites.

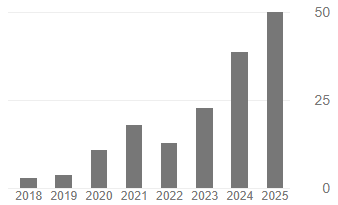

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Politeknik & Kolej Komuniti Journal of Engineering and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.